Manufacturing Processes Virtual Lab

Machines are inevitable & vital part of today’s manufacturing arena. The most common operations in the manufacturing unit are performed by operating on Lathe machines & CNC turning.

Lathe machine removes excess material from rotating workpiece by a hard cutting tool. Primary function of CNC is to control the machine tool, in process compensation, improved programming and operating features and diagnostics. CNC is widely used for lathe, drill press, milling machine, grinding unit, laser, sheet-metal press working machines, etc. Participants can analyse these processes through Tool Motion Controller and CNC Simulator and understand the basic principles of working.

Fluid Mechanics Virtual Lab

Fluid Mechanics Virtual Lab helps in determining the coefficient of discharge of a V notch, rectangular notch, impact of jet on the vanes, discharge through Venturimeter & friction in pipes.

The goals of the experiment includes determination of forces generated when fluid flow takes place over a solid object, applications of the control volume approach, demonstration of the momentum and energy equations, viscosity measurement and engineering corrections. By exploring experiments through virtual labs & using simulations, the participants can easily understand the concepts of discharges through devices.

Strength of Materials Virtual Lab

Strength of Materials Virtual Lab helps in determining various mechanical properties of a material such as Young’s Modulus, Shear Modulus, Hardness, Toughness, Deflection, Fatigue Strength, etc.

Main objective of the experiments is to find the impact resistance of mild steel, cast iron and hardness number of Brass, Aluminium & Spring steel, study of mechanical properties of mild steel specimen under tension load & compression, ultimate shear strength, double shear, etc. Participants can easily perform the experiments with ease by using the virtual lab.

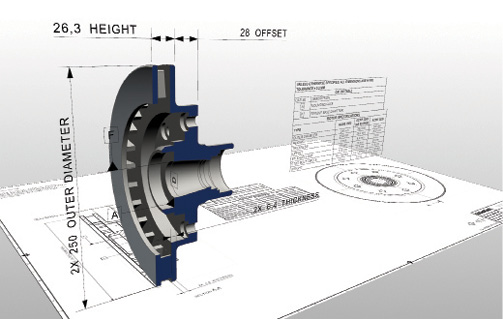

Machine Design Virtual Lab

As manufacturing technology evolves, impressive leaps is being seen when it comes to the creativity and complexity of machine design.

It mainly focusses on Adaptive Design, Developmental Design and New Design. Key technologies include Computer Aided Design & Manufacturing (CAD/CAM), fastening & joining, fluid power, manufacturing, engineering materials and motion control. Design of machine elements presents the fundamentals of Mechanisms, Load Analysis, Material Selection, Modification, Drawing and Manufacturing. Participants can use the virtual lab to understand various design tools/software used in designing mechanical tools such as AUTOCAD, PRO-E, CREO, CATIA, etc.

Heat & Transfer Virtual Lab

Heat & Transfer Virtual Lab provides the fundamental and industrial knowledge about modes of heat transfer, like conduction, convection and radiation, and their application.

In this Lab participants can study & perform experiments on the phase change, Heat Transfer by Conduction, Convection and Radiation, Newton’s Law of Cooling, Thermo Couple Seebeck Effect, Black Body Radiation, Characteristics of Thermistor. The various apparatus used to perform the experiments are Emissivity Measurement Apparatus, Critical Heat Flux Measurement Apparatus, Pin Fin Apparatus and Thermocouple Calibration System.

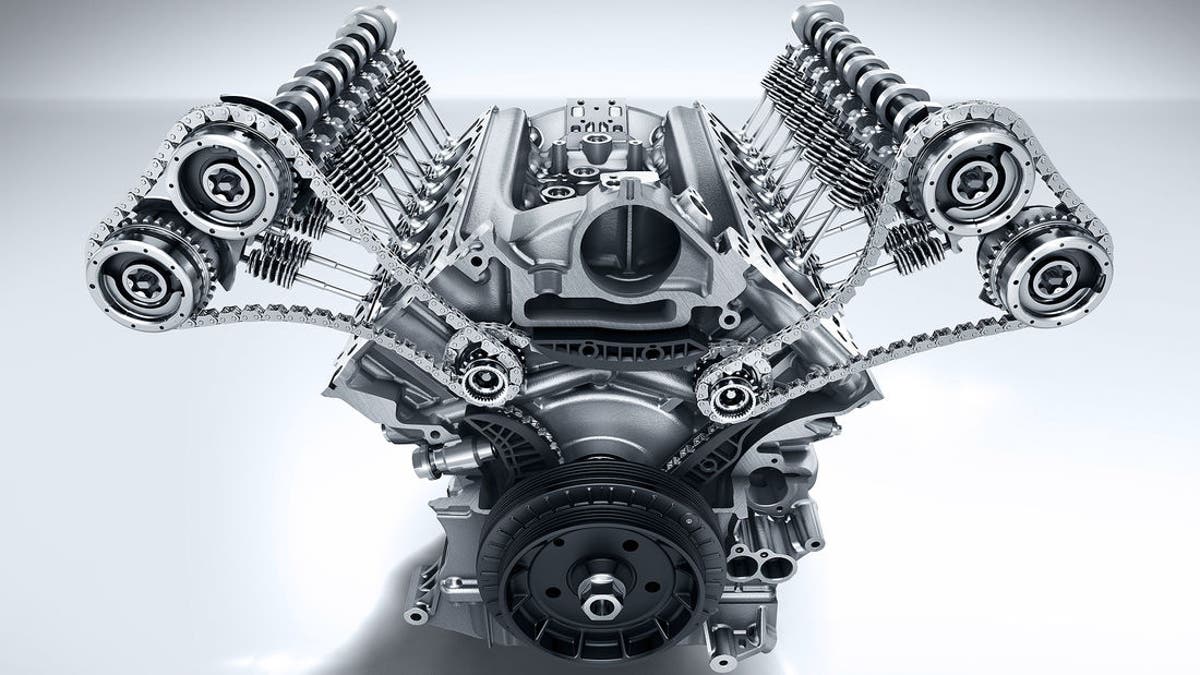

ICE Virtual Lab

Internal Combustion Engine Virtual Lab aims at exploring the concepts of basic laws of thermodynamics, heat transfer between various systems, conversion of heat to one form to another form,

Working of SI & CI Engines, evaluation of parameters of emissions and understands performance parameters of different engines. With the help of virtual lab, participants will understand the basic working principles of various engines such as 4-stroke multi-cylinder Petrol Engine, 4-stroke 4-cylinder Petrol Engine, 4-stroke 4-cylinder Diesel Engine, 4-stroke single cylinder Duel Fuel Engine, Variable Compression Ratio (VCR) Engine. The set up enables study of engine for brake power, BMEP, brake thermal efficiency, volumetric efficiency, specific fuel consumption, air-fuel ratio, frictional power, engine performance parameters like BP,IP and heat balance sheet.